The experience of creating world-class products such as Schmitz Cargo Bull, Wielton, MAN, etc. was used for the development of the trailer. Working with these giants of the automotive industry in Europe, I also learned to apply BEM (finite element method). So, this video is an excerpt from the phases of product development, using the finite element method (finite element method FEM). Where the trailer model is loaded with external forces. During the analysis, the potential is identified by optimizing the chassis in terms of durability, reducing weight, and increasing reliability. The FEMAP Nastran program was used for finite element analysis. The roots of the Nastran program go back to the time of the Apollo missions.

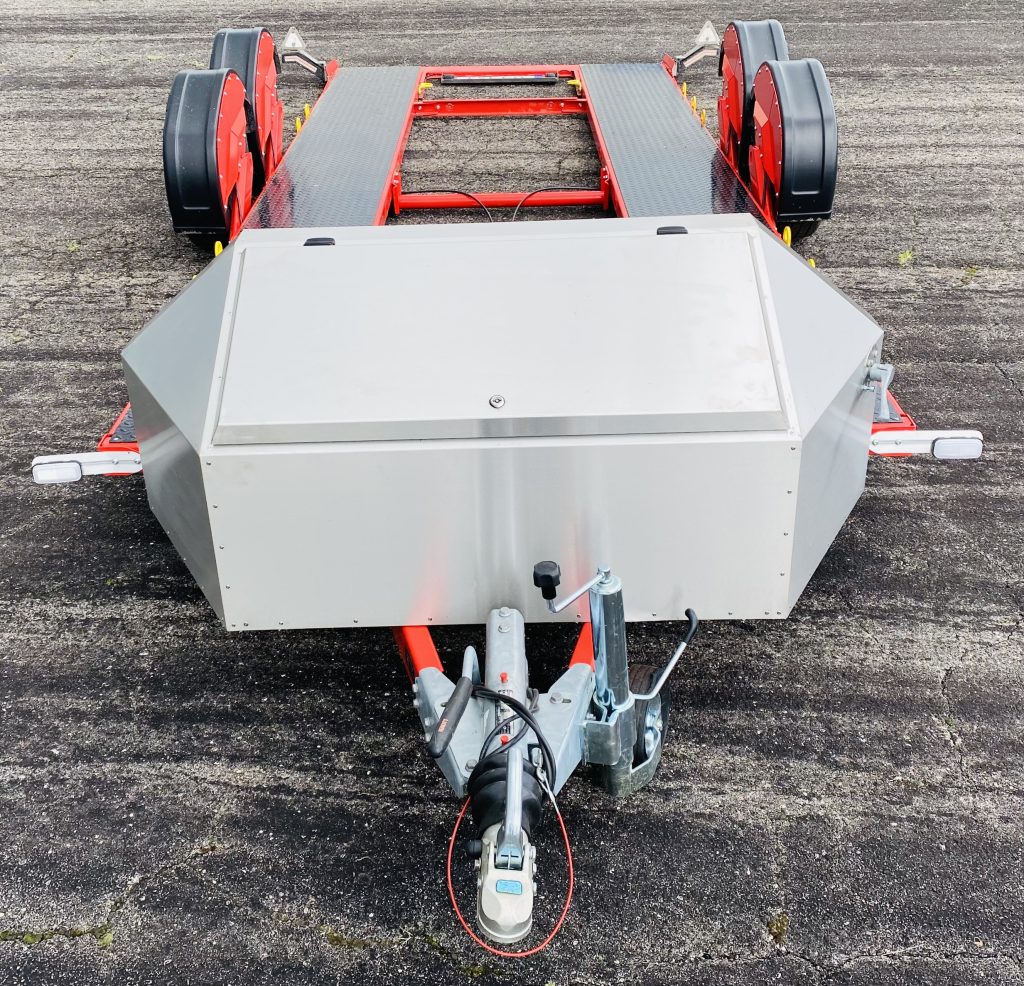

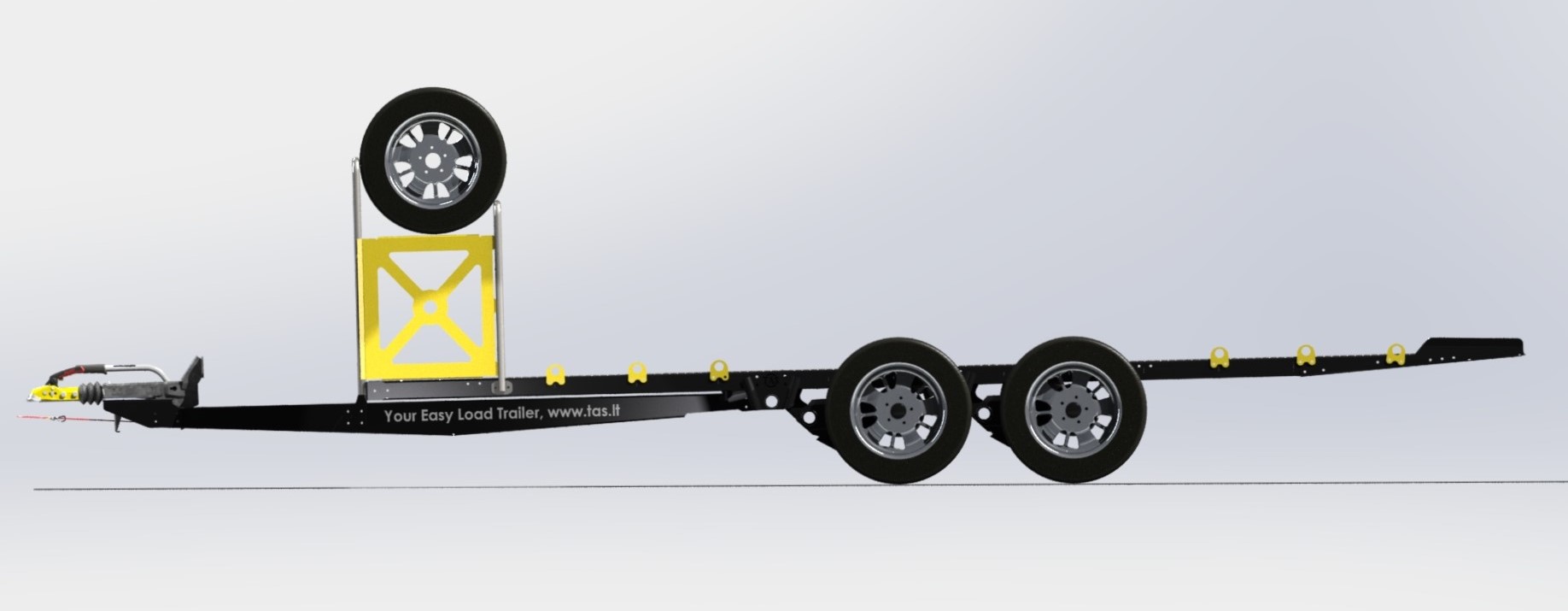

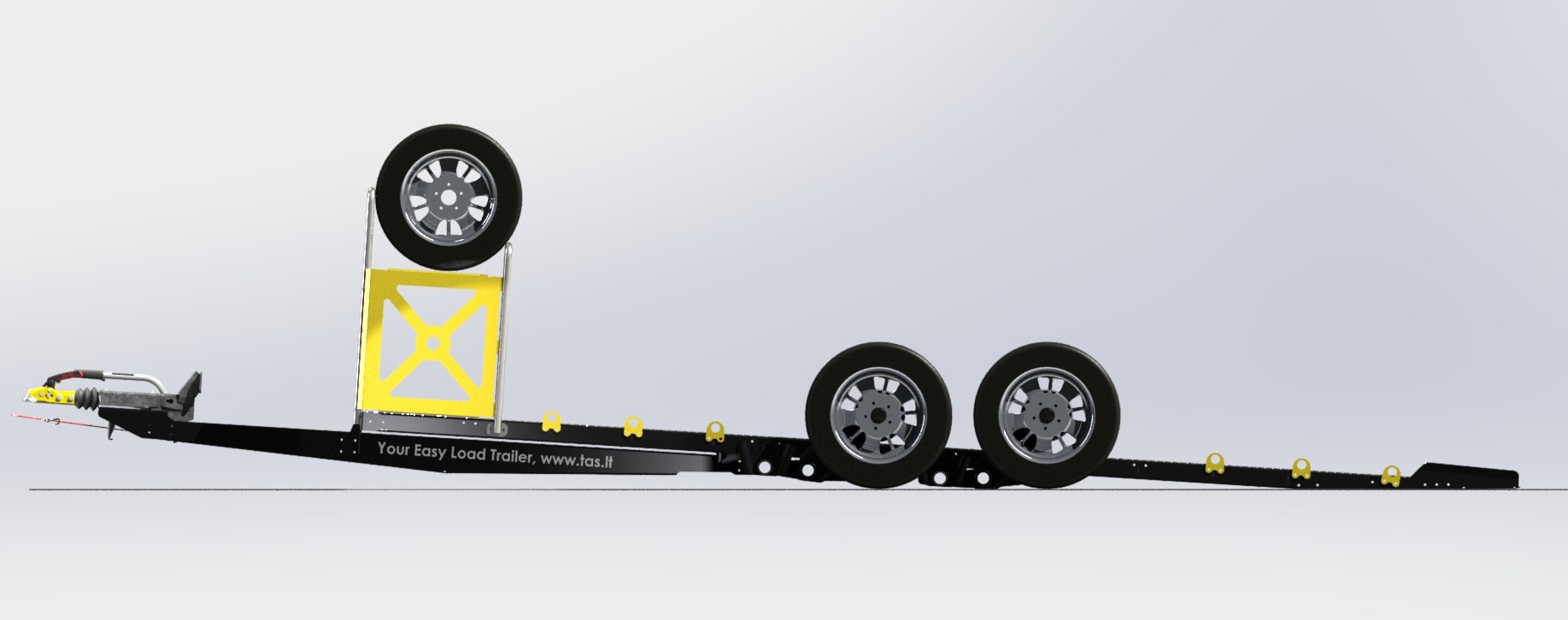

Product features

Trailer mass[kg] : 725

Useful length of the platform[mm] : 4930

Useful width of the platform[mm] : 2015

Total mass[kg] : 2700

Approach angle [⁰]: ~ 3.0 at a coupling height of 330 mm

Suspension type: pneumatic, adjustable height with programmable positions. Doesn’t depend.

Number of axles: 2 pcs.

News

T-shirt, blue

30,00 €

T-shirt, black

30,00 € Product on sale

Product on saleDock & Roll Race car trailer

20000,00 €